Top Soldering Technologies Revolutionizing Electronics Manufacturing in 2024

There are various soldering technologies in electronics:

- Laser soldering: Laser soldering is one of the most advanced and precise soldering technologies in modern electronics manufacturing. It uses a focused laser beam to heat and melt solder at specific points, enabling highly targeted and efficient soldering.

- Selective soldering: Selective soldering is an advanced soldering process designed for precise application of solder on specific areas of a printed circuit board. selective soldering focuses only on the through-hole components or other targeted areas.

- Robotics soldering: Robotic soldering is a process that uses automated robotic systems to perform soldering operations in electronics manufacturing. robotic soldering ensures that precision, consistency, and efficiency, especially for complex, high-volume soldering tasks.

- Low temperature soldering: Low-temperature soldering is a specialized soldering process that uses solder alloys with lower melting points.

- Eco-friendly soldering: Eco-friendly soldering technique reduces the environmental impacts of the electronics manufacturing process by minimizing harmful waste, energy consumption, and the use of hazardous material.

Key features of soldering:

- Precise Temperature Control: The temperature must be carefully managed to avoid overheating components while ensuring the solder melts properly.

- Filler Material: Solder acts as a filler material, typically made of a blend of metals like tin (Sn), lead (Pb), or lead-free alloys.

- Cleaning and Preventing Oxidation: Flux is used to clean the surfaces of the components and the PCB, removing oxides and contaminants.

- Manual and Automated Techniques:

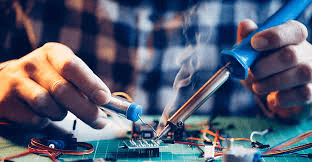

Manual Soldering: Involves the use of a soldering iron or gun by hand, commonly used in smaller-scale production, repairs, and DIY projects.

Automated Soldering: Techniques like wave soldering, reflow soldering, and selective soldering are used in high-volume production to automate the soldering process, ensuring consistency and efficiency.

- Rework and Repair:

Rework Capability: One of the key features of soldering is the ability to rework joints. If a solder joint is faulty or a component needs replacement, the solder can be re-melted and adjusted or replaced without damaging the surrounding components.

Repair of Circuits: Soldering provides an effective way to repair damaged circuits, whether through replacing components or fixing bad solder joints.

The choice of soldering technique:

- Types of components

- The choice of soldering technique

- Production Volume

- Complexity of PCB Design

- Cost Considerations

- Soldering Material

- Environmental and Safety Factors

- Speed and Throughput Requirements

Key precautions for soldering:

Safety: Wear protective glass and gloves, use fume extraction, and keep a fire extinguisher nearby.

Proper Equipment Setup: Check the soldering iron’s temperature, ensure the tip is clean.

Material Handling: Clean the PCB, ensure proper component placement, and handle components carefully

Work Area: Keep the workspace clean.

Soldering Technique: Apply heat correctly, avoid overheating components.

Application of Soldering:

Automotive Industry

Consumer Electronics Repair

Electronics Manufacturing

Medical Devices

Telecommunications