How to Test Servo Motors Using a Servo Motor ESC Tester

Servo motors are widely used in robotics, RC vehicles, and various automation projects due to their precision and control. To ensure your servo motor is functioning correctly, it’s essential to test it before deploying it in any project. In this blog, we’ll explore what a Servo Motor ESC Tester is, why testing is crucial, and provide a step-by-step guide to testing your servo motor.

What is a Servo Motor ESC Tester?

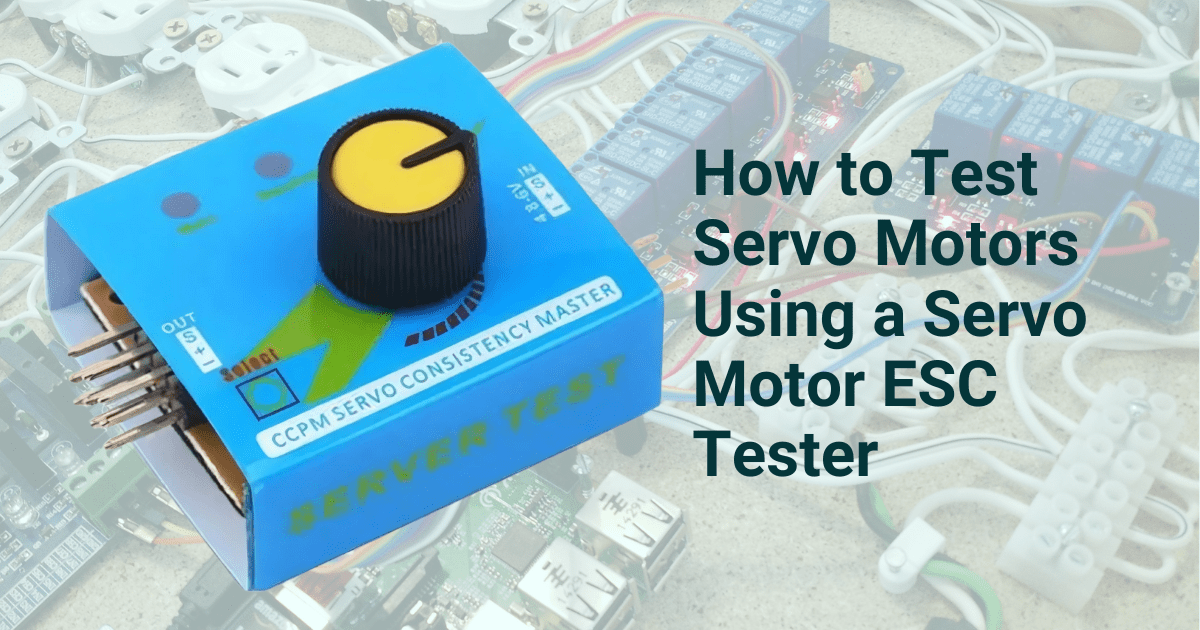

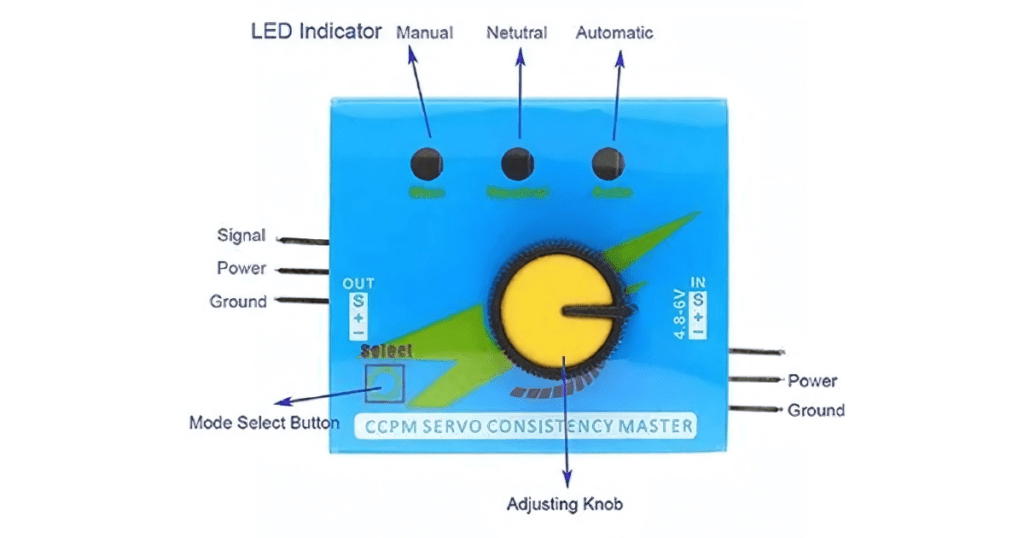

A Servo Motor ESC Tester is a handy device designed to test the performance and functionality of servo motors and Electronic Speed Controllers (ESCs). This tester can simulate the control signals usually provided by a microcontroller or RC receiver, allowing you to check whether your servo motor responds accurately to different inputs.

Key Features of a Servo Motor ESC Tester:

- Mode Selection: Different modes to simulate various signal inputs, including manual, automatic, and neutral.

- Pulse Width Modulation (PWM) Signal Generation: This feature allows the tester to simulate the PWM signals that control the servo motor’s position.

- Digital Display: Provides real-time data such as pulse width, signal frequency, and operating mode.

- Multiple Channels: Some testers can test multiple servos simultaneously.

Why is Testing Servo Motors Important?

Testing your servo motors is vital for several reasons:

- Ensuring Accuracy: Servo motors need to respond precisely to control signals. Testing ensures they hit the correct positions as intended.

- Avoiding Malfunctions: A faulty servo motor can cause a range of problems, from inaccurate movements to complete system failures.

- Diagnosing Issues: Testing allows you to identify and fix any issues before they become problematic in a live setup.

- Optimizing Performance: Testing helps fine-tune the motor’s response, leading to smoother and more efficient operation.

Step-by-Step Guide to Testing a Servo Motor with an ESC Tester

Step 1: Gather Your Tools and Materials

Before you begin, ensure you have the following items ready:

- A Servo Motor ESC Tester

- The servo motor you want to test

- A power source (usually a 4.8V to 6V battery or regulated power supply)

- Connecting cables and adapters

- A safe, stable work area

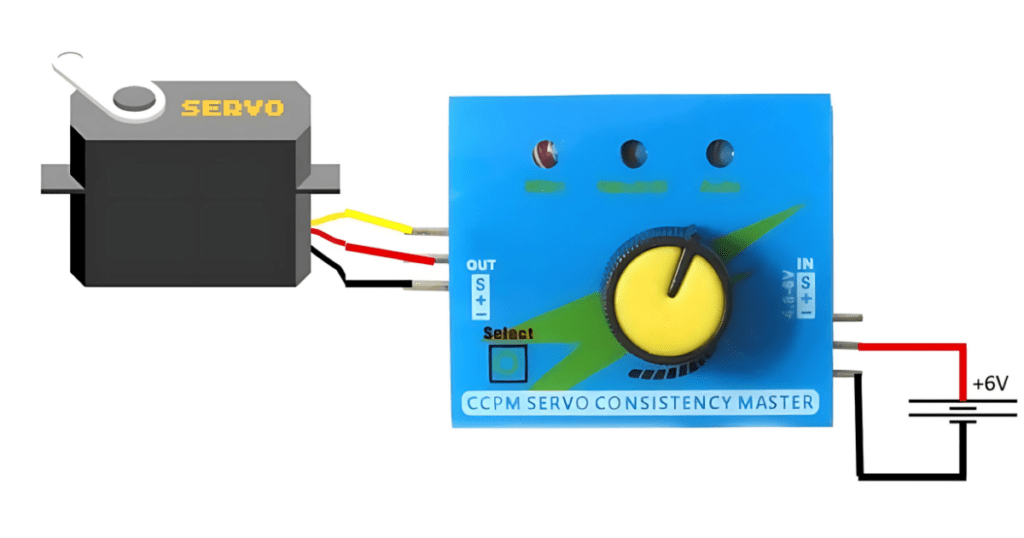

Step 2: Connect the Servo Motor to the Tester

- Power Connection: Connect the ESC tester to your power source. Ensure the voltage is appropriate for both the tester and the servo motor.

- Servo Connection: Plug the servo motor’s connector into the corresponding port on the ESC tester. The connector usually has three wires: signal, power (VCC), and ground (GND). Ensure these are connected correctly.

Step 3: Set the ESC Tester to the Appropriate Mode

- Manual Mode: In this mode, you can manually adjust the PWM signal using the tester’s knob or buttons. This is useful for checking the servo motor’s response to specific positions.

- Automatic Mode: This mode cycles the servo through its full range of motion automatically. It’s useful for endurance testing or checking if the motor can handle continuous operation.

- Neutral Mode: This sets the servo to its neutral position (usually 90 degrees). This is useful for calibrating the servo or ensuring it returns to a baseline position.

Step 4: Conduct the Test

- Manual Testing: Slowly adjust the PWM signal using the tester. Observe the servo motor’s movement. It should move smoothly to the corresponding position without jittering or stalling.

- Automatic Testing: Set the tester to automatic mode. The servo should move smoothly through its entire range of motion. Listen for any unusual noises, and ensure the motor does not overheat during the test.

- Neutral Position Testing: Switch to neutral mode and observe if the servo motor returns to its central position. It should settle at the neutral point without oscillation or delay.

Step 5: Analyze the Results

- Position Accuracy: Ensure the servo motor moves to the exact position corresponding to the PWM signal. Any deviation could indicate a problem with the motor or the signal.

- Smoothness of Movement: The servo should move smoothly without jittering or sticking. If the movement is not smooth, the motor may be damaged or there might be an issue with the signal quality.

- Noise and Vibration: Listen for any unusual noises or excessive vibration. These could be signs of mechanical issues within the servo.

- Temperature Check: After running the servo motor for a few minutes, touch the motor casing. It should be warm but not hot. Overheating could indicate that the motor is under too much strain or that there is an internal fault.

Step 6: Disconnect and Store the Equipment

After testing, carefully disconnect the servo motor and power supply from the tester. Store your equipment in a safe place to ensure it remains in good working condition for future use.

Troubleshooting Common Issues

- Servo Motor Not Responding: Check the power supply and connections. Ensure the servo is compatible with the tester’s output signal.

- Inconsistent Movements: This could be due to poor signal quality or a faulty servo. Try using a different tester or motor to isolate the issue.

- Overheating: If the servo motor is overheating, ensure it is not being overdriven or that the load is not too high. Consider using a different servo motor for the application.

Conclusion

Testing your servo motors with a Servo Motor ESC Tester is an essential step in ensuring the reliability and performance of your projects. By following the outlined steps, you can confidently assess the functionality of your servo motors, identify potential issues, and optimize their performance. Regular testing not only helps prevent failures but also enhances the precision and efficiency of your work.