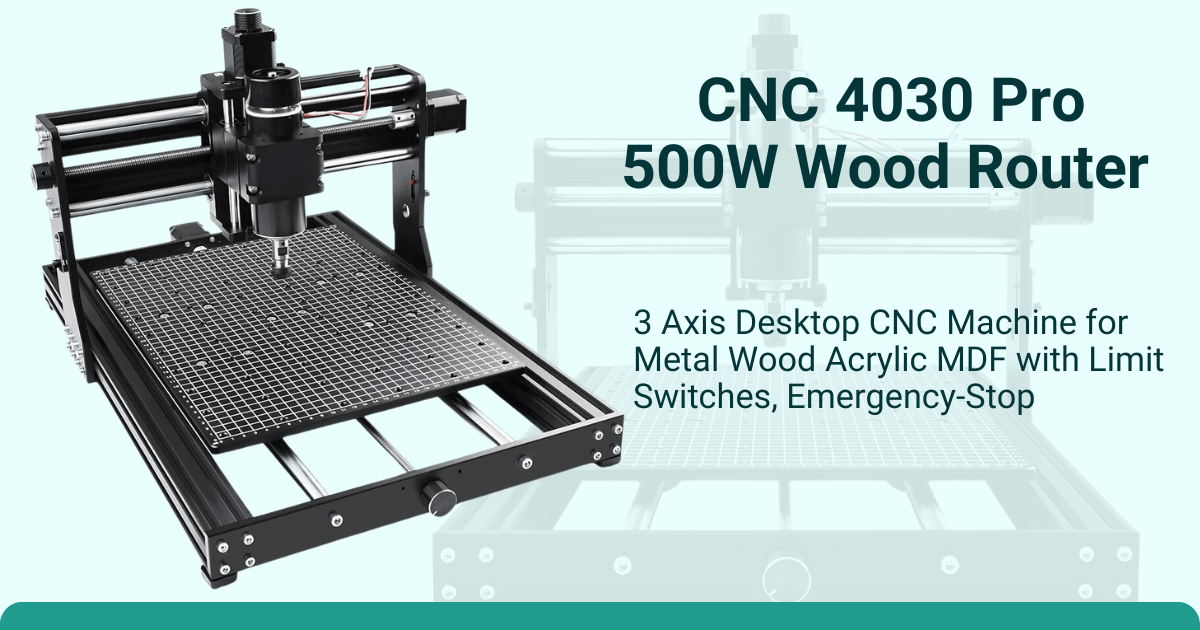

4030 CNC MACHINE

The 4030 CNC machine is a medium range CNC router designed for small businesses, and makers who need a larger working area than smaller models but still want a machine that’s affordable and easy to use. Its working area 400mmx300mm.

Key features of 4030 machine:

Strong Frame: Made from aluminium and steel, ensuring durability and stability during operation. High rigidity allows for precise machining, even under heavier loads.

Powerful Spindle Motor: Typically comes with a 500W to 1.5kW spindle motor.

Suitable for wood, plastic, acrylic, and soft metals like aluminium.

Adjustable Z-Axis: The Z-axis typically has a manual or automatic adjustment.

Wide Material Compatibility: Capable of working with a variety of materials such as Wood, plastic, soft metal.

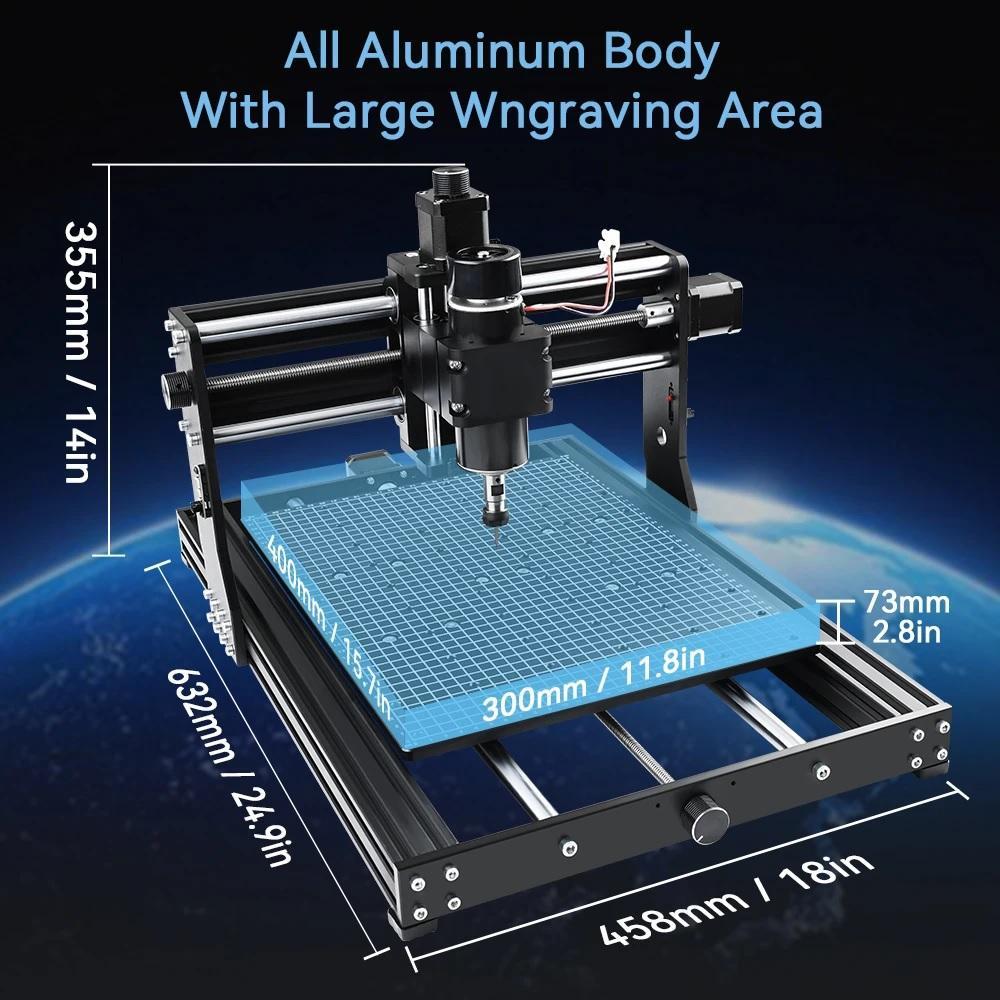

Working area of 4030 CNC machine:

X-Axis (Width): 400mm

The X-axis determines the horizontal movement from left to right.

Y-Axis (Depth): 300mm

The Y-axis controls the front-to-back motion of the spindle or cutting tool. With a 300mm depth, CNC machine can work on materials that are 30 cm deep, which is suitable for most small to medium-scale projects.

Z-Axis (Height): 70mm

The Z-axis handles vertical motion, controlling how the spindle moves up and down, typically for controlling cutting depth.

Why Choose a 4030 CNC Machine Over Other CNC Machines:

Larger Working Area: 4030 CNC provides a larger work area compared to smaller CNC machines.

Higher Precision and Stability: This construction allows for more precise cuts and better quality finishes on a wide range of materials.

Versatility with Various Materials: Suitable for wood, acrylic, PVC, and light metals (such as aluminium or copper).

It can handle larger workpieces and thicker materials, giving you more flexibility for various applications.

More Suitable for Small Businesses and Production: It can handle small-scale production custom parts, engraving, and prototyping tasks efficiently.

Setup of 4030 CNC machine:

Unbox and check all parts.

Assemble the frame, motors, and spindle.

Wire the motors, spindle, and limit switches to the control board.

Connect the power supply and install CNC software (e.g., GRBL, Mach3).

Calibrate the machine, set home positions, and test movement.

Load G-code and secure material.

Start your project with proper tool settings.

Application of 4030 CNC machine:

Circuit Board Manufacturing.

Jewellery Making.

Metalworking.

Acrylic and Plastic Processing.

Woodworking.