6560 CNC MACHINE

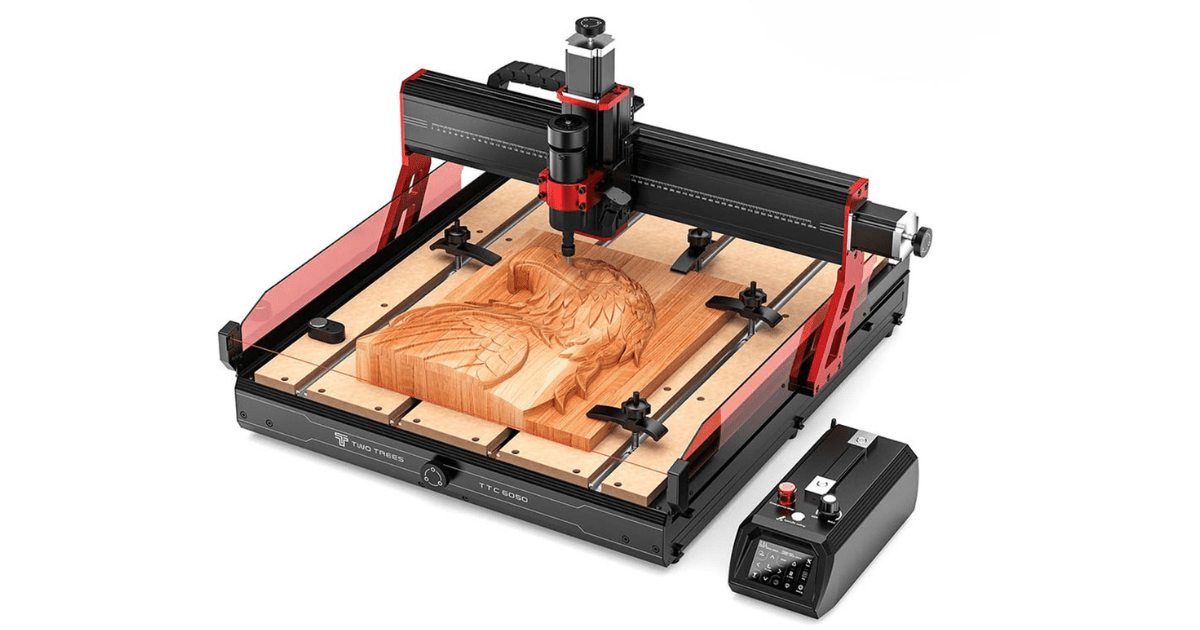

The 6560 CNC machine features a 65×60 cm working area, making it ideal for medium to large projects. It offers high precision for cutting, milling, engraving, and prototyping on materials like wood, metal, and plastic. The machine includes a rigid metal frame, high-power spindle, and stepper motors for accurate movement.

Key features of 6560 CNC machine:

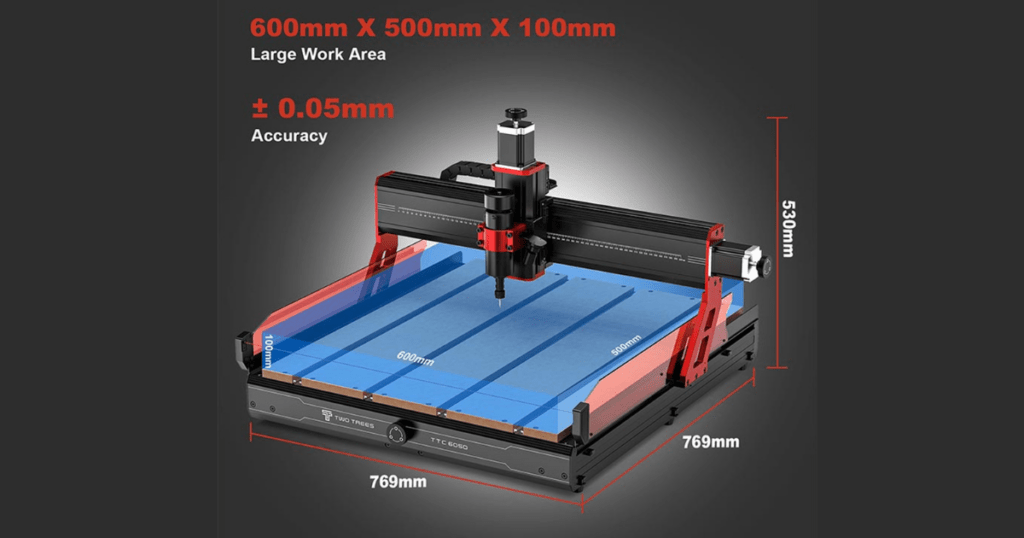

Working Area: 65×60 cm working area, providing a larger workspace for medium to large projects.

Frame: Rigid metal frame construction, typically made of aluminium and steel, ensuring stability and precision during operations.

High-Power Spindle: with a high-power spindle (500W to 2.2kW or higher), ideal for cutting and engraving various materials such as wood, acrylic, plastic, and light metals.

Precision and Accuracy: High precision and accuracy with stepper motors or servo motors controlling the X, Y, and Z axes, providing smooth and reliable movements.

Multi-Material Capability: Capable of working with a wide range of materials including wood, plastics (acrylic, PVC), light metals (aluminium, brass), and composite materials.

Tool Holder: Adjustable tool holder for various cutting and milling tools, providing flexibility for different tasks.

Working area of 6560 CNC machine:

X-Axis (Left to Right) – 65 cm

The X-axis controls the horizontal movement of the cutting tool or spindle.

A 65 cm width allows the machine to work on relatively large materials in a single pass.

Y-Axis (Front to Back) – 60 cm

The Y-axis moves the material or tool front to back, expanding the work area.

A 60 cm length makes it useful for working on longer materials, such as engraving wooden boards, cutting metal sheets, and machining prototypes.

Z-Axis (Up and Down) – 5 cm to 15 cm (Varies by Model)

The Z-axis moves the spindle or cutting tool up and down.

The Z-axis height varies between 5 cm to 15 cm, depending on the machine model and spindle configuration.

Why Choose a 6560 CNC Machine Over Other CNC Machines:

Larger Working Area (65×60 cm) Offers more workspace than smaller machines.

High Precision & Stability: Uses stepper or servo motors for smooth and precise movement across all axes.

Versatile Material Compatibility: Can work with wood, acrylic, plastic, aluminium, brass, and composite materials. Suitable for both soft materials (wood, plastic) and light metals (aluminium, brass, copper).

High-Power Spindle & Performance: a powerful spindle (500W to 2.2kW), allowing for deeper cuts and faster material removal.

Multi-Purpose Applications: Suitable for woodworking, metalworking, sign-making, PCB milling, 3D carving, and prototyping.

Cost-Effective: More affordable than industrial CNC machines

Setup for 6560 CNC Machine:

1.Assemble the Frame:

Secure the aluminium and steel frame.

Mount the X, Y, and Z-axis rails and motors.

2.Install the Spindle & Tool Holder

Attach the spindle (500W–2.2kW) to the Z-axis.

Secure the collet and cutting tool.

3.Connect the Electronics

Wire the stepper or servo motors to the controller board.

Connect the spindle motor to the power supply.

Attach the limit switches and emergency stop button.

4.Software Installation

Install GRBL, Mach3, or UCCNC on your PC.

Configure the machine’s step/mm settings for accurate movement.

5.Calibrate the Machine

Home the machine to set the X, Y, and Z zero positions.

Test movement in all directions.

6.Material & Tool Setup

Secure the workpiece using clamps or a vacuum bed.

Set the Z-axis height for proper cutting depth.

7.Run a Test Cut

Load a sample G-code file and run a test operation.

Adjust feed rate, spindle speed, and toolpath as needed.

Application of 6560 CNC machine:

Woodworking & Furniture Making

Metalworking & Light Industrial Use

Acrylic & Plastic Fabrication

PCB Prototyping & Electronics

Jewellery & Crafts.